This station focuses on the development of sophisticated control systems that manage and regulate the behavior of LVADs and related test setups. Mathematical models using linear and nonlinear control methods such as Proportional-Integral-Derivative (PID), Lyapunov and Integral Backstepping are designed to regulate critical parameters such as pressure, volume, flow and pump angular velocity. These control systems are designed to provide high precision and stability and ensure that the LVAD operates in accordance with the desired performance characteristics.

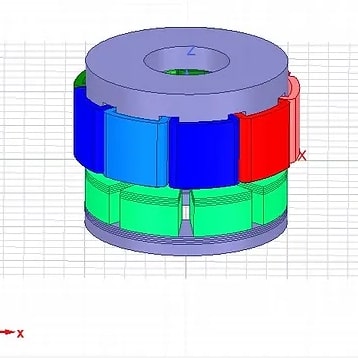

The focus here is on the precise design and manufacture of the micro motor required to drive the LVAD. Using Maxwell electromechanical simulation software, geometric optimizations and finite element analyses are performed based on predefined parameters such as torque, speed and power efficiency. Following the simulations, the motor components undergo a rigorous manufacturing process, followed by assembly and integration with the LVAD. This ensures the smooth operation of the motor within the device, delivering reliable and continuous performance.

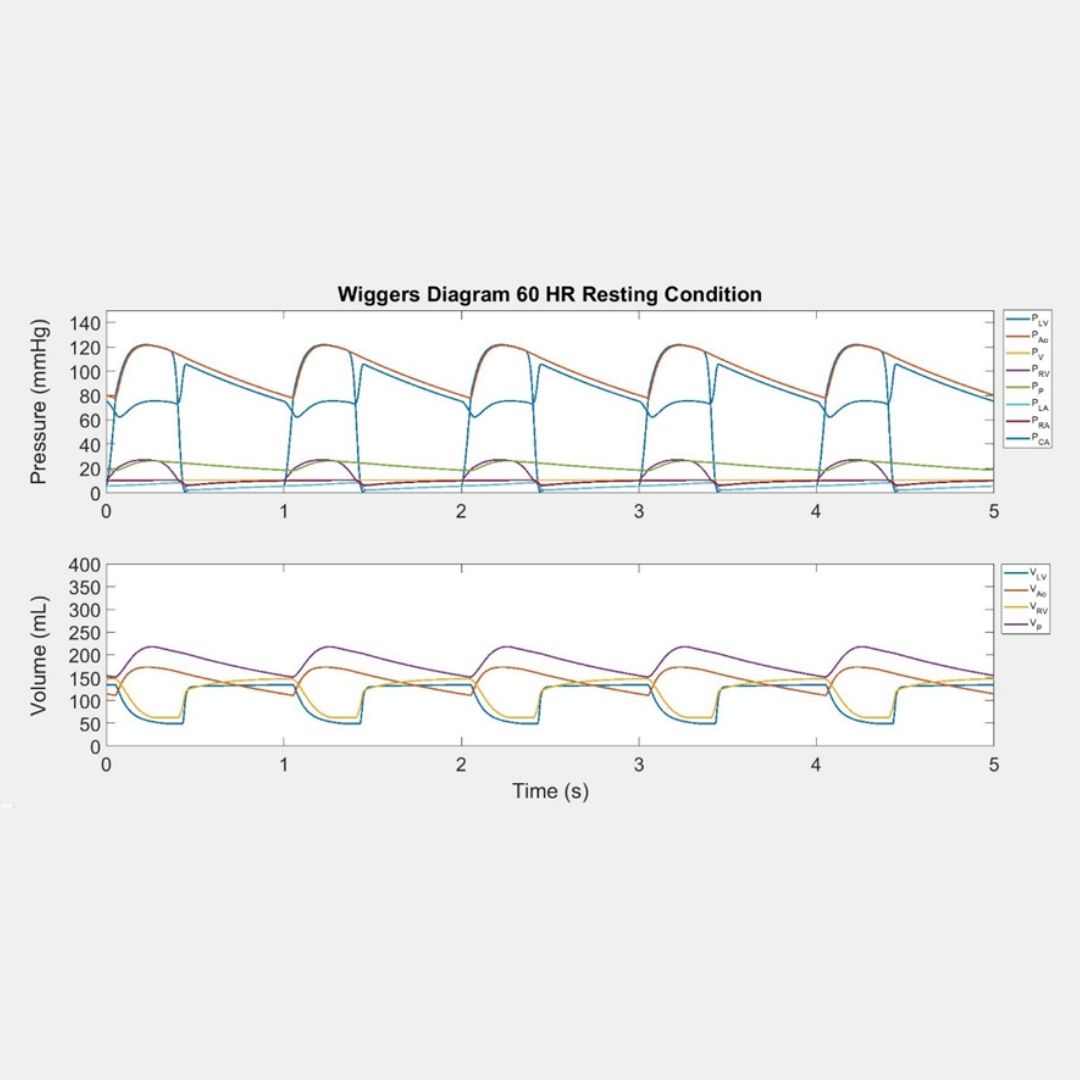

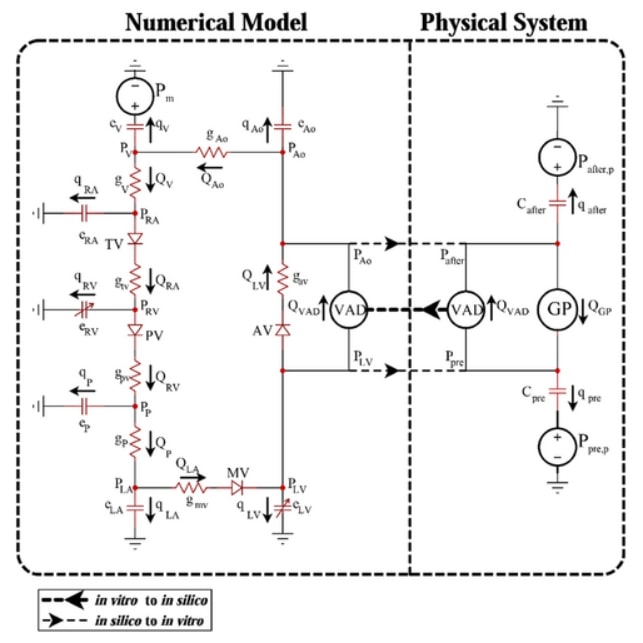

This station uses an electrical simulation to convert the dynamic behavior of the cardiovascular system into solvable equations. Different numerical modeling methods, such as cumulative parameter modeling and multi-scale simulations, are used to replicate the responses of the cardiovascular system under various physiological conditions. These simulations are invaluable for studying the effects of LVAD interventions and help predict outcomes and improve device performance prior to actual implementation.

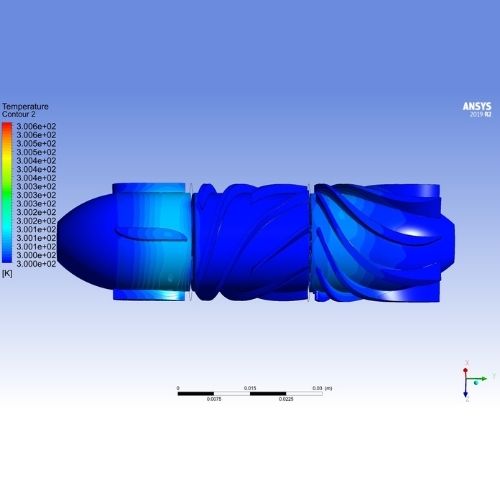

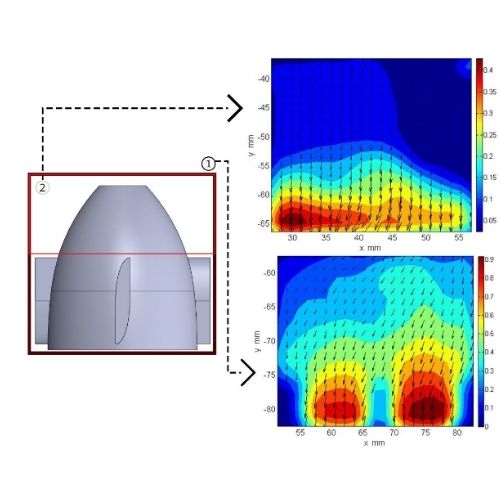

This station focuses on optimizing the design of Left Ventricular Assist Device (LVAD) turbines, aiming to achieve superior hemodynamic performance. Using advanced Computer Aided Design (CAD) and Computational Fluid Dynamics (CFD) software, the design process becomes highly iterative. Each iteration involves refining the turbine based on extensive simulation analysis to optimize parameters such as blood flow, pressure and shear stress. The goal is to improve the overall efficiency and safety of the LVAD by minimizing hemolysis (damage to red blood cells) and thrombosis (blood clots).

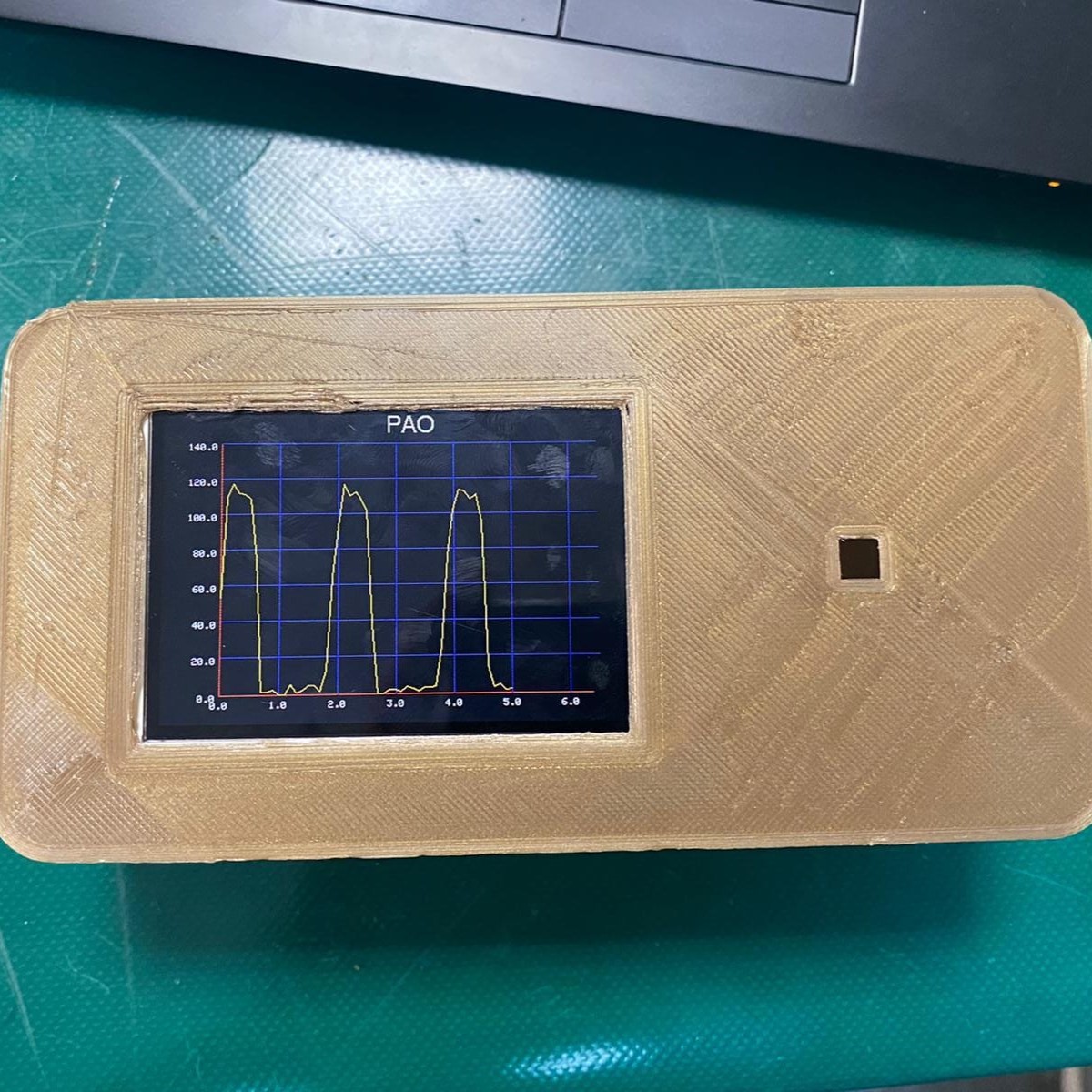

This station focuses on the development of robust communication protocols for real-time monitoring of LVADs and patient data. Data is converted into formats accessible through user-friendly websites and mobile apps, enabling continuous monitoring by both patients and healthcare providers. In the event of abnormal sensor readings, doctors are sent immediate notifications via text or email, enabling rapid intervention. All sensor data is securely stored for up to 15 days, providing a comprehensive record for ongoing analysis and monitoring.

This station uses Particle Image Velocimetry (PIV) to experimentally visualize the flow dynamics inside the LVAD. PIV provides high-resolution, quantitative flow measurements, which are compared to numerical CFD simulations to validate and refine device performance. Images captured during the experiments are processed using Insight 4G software and Tecplot and MATLAB are used for detailed visualization and analysis, ensuring that the LVAD design meets stringent safety and effectiveness standards.

Here, a hybrid model circuit is developed that combines numerical and physical elements and simulates cardiovascular dynamics. The mock-up circuit uses hydraulic and pneumatic systems to accurately replicate parameters such as blood pressure, volume and flow. This hybrid approach provides a controlled and realistic environment in conditions very close to real-life physiological scenarios to test and optimize LVAD characteristics.

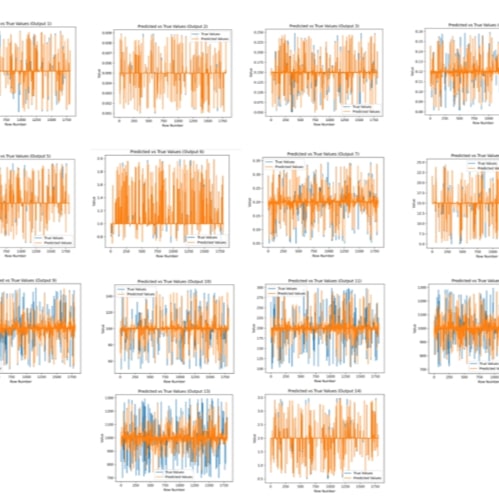

Machine learning techniques play an integral role in the optimization of various processes in our laboratory. Algorithms are developed to improve the efficiency and performance of turbine and engine geometry. Furthermore, machine learning automates the tuning of system and control parameters, ensuring precision and reliability in experimental setups. These methods contribute to the continuous improvement and innovation of LVAD technology, paving the way for more efficient and reliable devices.

© PCL All Rights Reserved. Coded by Funda Nur Civelek